Call us at (408)988-3753

Tempered Glass

There are government standards (ANSIZ97.1) for what constitutes Safety Glass. To be approved as a manufacture of safety glass several sample pieces of the material is run through a gauntlet of tests. Most of them consist of having a secure sample of glass impacted with a leather bag filled with lead shot. The tests are run using different weighted bags. Under some conditions the glass must not break. Then there are conditions where the glass can break, but the bag can't go through the sample, and no pieces of glass larger than a certain size can fall out. The test is increased until the bag goes through the the sample, but no piece of glass larger than the permitted size can be released from the sample. All of these tests are geared to try to prevent severe injures. Glass is glass and when it breaks it is easy to get cuts. With safely glass you may get cut, but you have less of a chance of loss of life or limb.

There are government standards (ANSIZ97.1) for what constitutes Safety Glass. To be approved as a manufacture of safety glass several sample pieces of the material is run through a gauntlet of tests. Most of them consist of having a secure sample of glass impacted with a leather bag filled with lead shot. The tests are run using different weighted bags. Under some conditions the glass must not break. Then there are conditions where the glass can break, but the bag can't go through the sample, and no pieces of glass larger than a certain size can fall out. The test is increased until the bag goes through the the sample, but no piece of glass larger than the permitted size can be released from the sample. All of these tests are geared to try to prevent severe injures. Glass is glass and when it breaks it is easy to get cuts. With safely glass you may get cut, but you have less of a chance of loss of life or limb.

Tempered Safety Glass

There are several types of safety glass. Tempered glass is basically stronger than regular glass, and when it breaks it shatters into little pieces of glass. This the preferred glass for shower doors. Laminated glass takes a different approach to meeting the safety standards. This glass is usually two pieces of normal glass laminated together with a gummy jell. This is the safety glass used in car windshields. In a car accident they don't want your head to go through the glass, and they don't want you to be peppered with glass shards. There is also Wire Glass which was used in showers for a short time before tempered glass became prevalent. It is still used as a type of safety glass where their are fire codes involved.

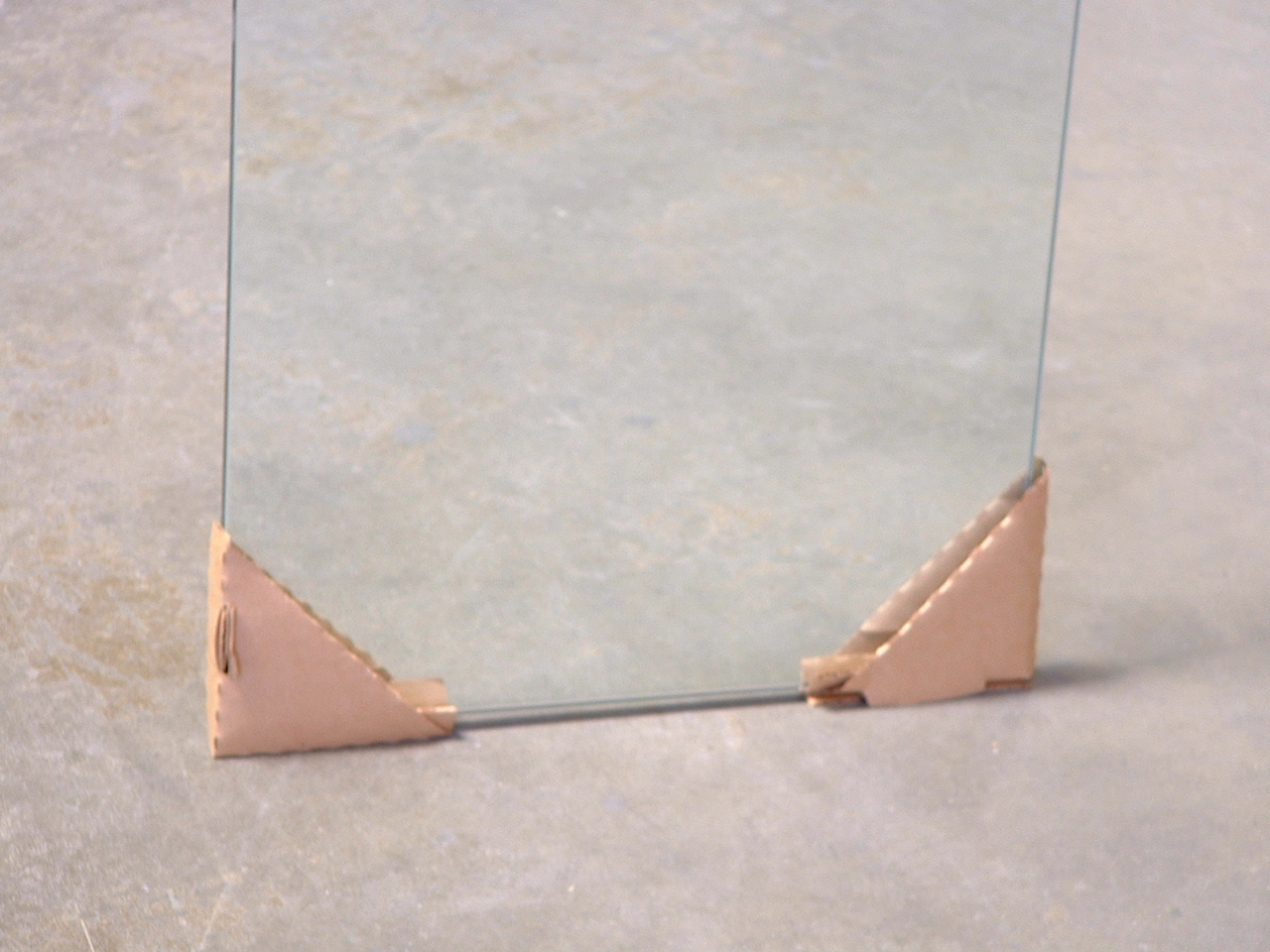

Corner Protectors & Plastic Wrap

Corner Protectors

Broken Tempered Glass

Making Tempered Glass:

To make tempered glass you start with standard glass and heat it up until it is soft and pliable, about 1200 degrees, and then quench it with cold air. The outside skin of glass cools first and solidifies. As the inside core area starts to cool it tries to contract or shrink in size but it can't because the outside skin has already become ridged. This causes internal stress to build up in the glass. If a piece of tempered glass is broken, it releases this trapped stress and instantly shatters into small pieces. Once made a piece of tempered glass can't be modified. The outside surface is regular glass so you can still get minor chips and scratches in the outside surfaces and and on the edges, but you can't cut or drill it without the glass breaking into small pieces.

Identifying Tempered Glass:

The manufacture of the tempered glass must put an identifying mark on each piece of glass which comes out of their furnace. The makers of the tempered glass don't want to take away from the beauty of the glass, so the marks can be hard to see. We try to have this identification mark placed in one of the bottom corners of each piece of glass. You can verify that the glass has been tempered by finding the mark. If you have your installation inspected by the building department the inspector will look for these marks.

Guidelines for Handling Tempered Glass

As explained above the outside skin of tempered glass is standard glass. The edges and corners are where the glass is the most vulnerable. Here are four golden rules for working with tempered glass.

- Wear safety glasses.

- Thermally stablize the glass before removing it from the crate. Going from the outside cold into a warm house is thremally shocking the glass. It becomes sensitive to getting edge slivers. If possible bring the shower door up to room trmperature before removing it from the crate.

- Always leave the corner protectors on the glass.

- Don't walk the glass from corner to corner just because you have the corner protectors on.

- Never stand the glass directly on cement, tile, metal, or on the bottom of the tub.

- Use Suction Cups to aid in lifting and moving the glass.